How Electrical Maintenance Enhances Workplace Safety

Table Of Contents

Training Employees on Electrical Safety

Understanding electrical safety is crucial for all employees, regardless of their role within an organisation. Proper training equips workers with the knowledge and skills necessary to handle potential electrical hazards effectively. It encourages adherence to established protocols that minimise risks. Regular training sessions reinforce these principles, ensuring that employees are familiar with the latest safety guidelines and industry standards.

Incorporating practical exercises during training can significantly enhance learning outcomes. Simulating real-life scenarios helps to prepare employees for emergencies they might encounter. Participants learn to identify hazards and respond appropriately, fostering a culture of safety within the workplace. Ongoing education serves to keep safety at the forefront of employees’ minds, which is essential for maintaining a secure work environment.

Promoting Awareness and Best Practices

Creating a culture of electrical safety within the workplace is crucial for minimising risks. Regularly educating employees about potential hazards and safe practices can significantly reduce accidents. Workshops and seminars can provide essential information on recognising faulty equipment and understanding proper handling procedures. Visual aids, such as posters or infographics, can serve as constant reminders of electrical safety protocols, ensuring that best practices are at the forefront of employees’ minds.

Encouraging an open dialogue about safety concerns can reinforce the importance of being vigilant. Employees should feel comfortable reporting any electrical issues without fear of repercussions. Establishing a reporting system for maintenance requests can lead to quicker resolution of potential hazards. Routine safety meetings can also foster an environment where sharing experiences and tips becomes normal, ultimately creating a workplace that prioritises safety and well-being.

The Impact of Faulty Equipment

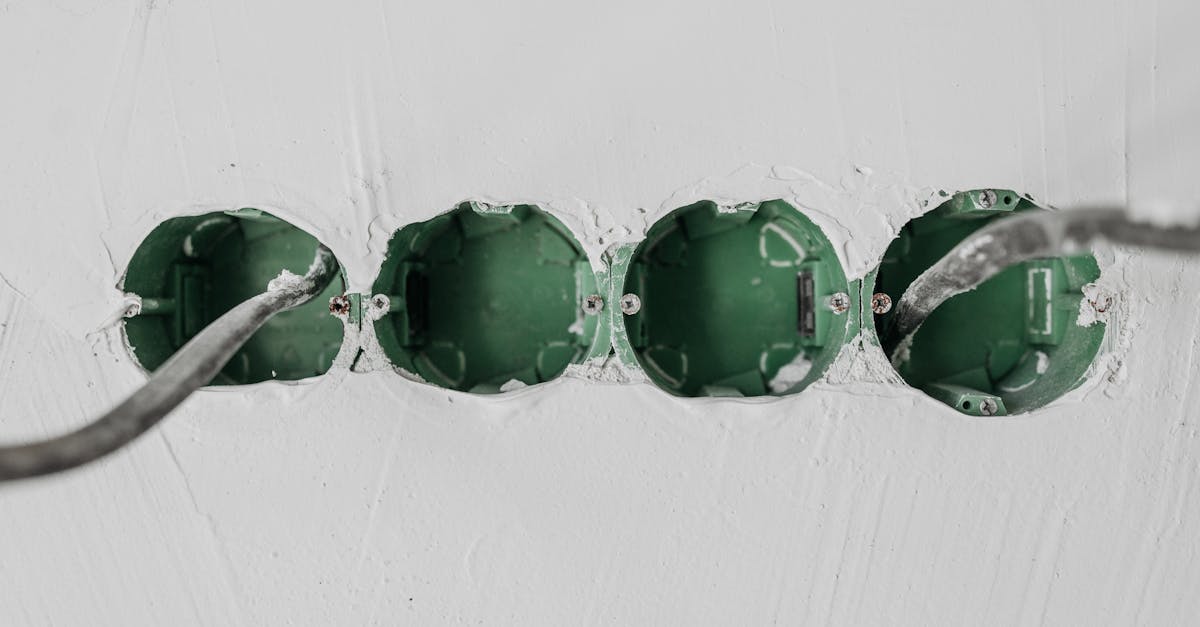

Many workplace incidents stem from faulty electrical equipment. These malfunctions can create hazardous conditions, leading to electrocutions or fires. Equipment such as worn-out circuits, frayed cables, and malfunctioning tools pose significant risks to employees. Regular inspections and maintenance are essential for identifying and addressing these issues before they escalate into serious accidents.

The consequences of neglecting faulty equipment can extend beyond immediate risks. Companies may face downtime, resulting in lost productivity and financial strain. Additionally, legal ramifications can arise if incidents lead to injury or damage. Ensuring all electrical systems function properly not only safeguards employee welfare but also protects the organisation’s reputation and operational efficiency.

Consequences for Workplace Safety

The presence of faulty electrical equipment poses serious risks within a workplace environment. Equipment malfunctions can lead to workplace injuries, electrical fires, and even fatalities. Employers face not only the physical hazards associated with these incidents but also potential legal ramifications. If safety protocols are not adhered to, the organisation may be held liable for negligence, resulting in costly lawsuits and damage to its reputation.

Inadequate maintenance of electrical systems can lead to unplanned downtimes and disruptions in productivity. Employees may feel less safe working around unreliable equipment, which can affect morale and overall job satisfaction. A culture that prioritises electrical safety fosters trust and reliability among staff. It establishes an environment where employees are not only aware of hazards but are empowered to report issues, creating a proactive approach to workplace safety.

Using Technology for Electrical Maintenance

Modern electrical maintenance increasingly relies on advanced technology to streamline processes and enhance safety. Tools such as predictive maintenance software allow teams to monitor equipment in real time, identifying potential faults before they escalate into serious issues. This proactive approach not only reduces downtime but also mitigates the risks associated with electrical failures, ensuring that safety protocols are upheld across the workplace.

Innovations in technology have introduced smart devices that facilitate efficient monitoring of electrical systems. These devices can detect anomalies in electrical performance and alert maintenance personnel immediately. Furthermore, cloud-based platforms enable teams to securely store and analyse data, aiding in the identification of trends and enabling informed decision-making. By integrating these technologies, workplaces can maintain a safer environment while optimising operational efficiency.

Innovations in Monitoring and Reporting

Technological advancements have transformed the way electrical maintenance is conducted in the workplace. Smart sensors and IoT (Internet of Things) devices now monitor electrical systems in real-time. These technologies enable companies to gather data on equipment performance and predict potential failures before they occur. By employing machine learning algorithms, businesses can analyse trends and identify possible risks. Such proactive measures enhance safety and reduce the likelihood of accidents associated with faulty electrical equipment.

Moreover, cloud-based platforms have improved reporting practices, making it easier for teams to access information on maintenance activities. This centralised data allows for more effective communication among workers, fostering a culture of safety by sharing insights and solutions. Mobile applications also empower technicians to document findings immediately, streamlining the process of addressing issues and scheduling repairs. With these innovations, organisations can maintain a higher standard of electrical safety while optimising operational efficiency.

FAQS

Why is training employees on electrical safety important?

Training employees on electrical safety is crucial as it equips them with the knowledge and skills to recognise hazards, follow safe practices, and respond effectively in emergencies, ultimately reducing the risk of accidents and injuries in the workplace.

What are some best practices for promoting electrical safety at work?

Best practices for promoting electrical safety include regular training sessions, clear signage for electrical hazards, routine safety audits, encouraging open communication about safety concerns, and implementing strict protocols for using electrical equipment.

What are the risks associated with faulty electrical equipment?

Faulty electrical equipment can lead to severe risks, including electrical shocks, fires, and equipment failures. These incidents can cause injuries to employees, damage to property, and lead to significant downtime for businesses.

How can technology improve electrical maintenance and safety in the workplace?

Technology can enhance electrical maintenance and safety through innovations such as real-time monitoring systems, predictive maintenance tools, and automated reporting software. These solutions help identify potential issues before they escalate, ensuring a safer work environment.

What should a workplace do in case of an electrical emergency?

In case of an electrical emergency, the workplace should immediately shut down power to the affected area if safe to do so, call emergency services, evacuate personnel if necessary, and provide first aid to anyone injured while waiting for professional help.

Related Links

Emergency Electrical Maintenance: Preparing Your Business for Unexpected IssuesThe Cost-Effectiveness of Regular Electrical Maintenance for Offices

Maintaining Compliance: Electrical Maintenance Requirements for Businesses

Upgrading Your Electrical Systems: When and Why for Commercial Facilities

The Role of Electrical Maintenance in Business Continuity

Benefits of Preventative Electrical Maintenance in Commercial Spaces